Storage Racks

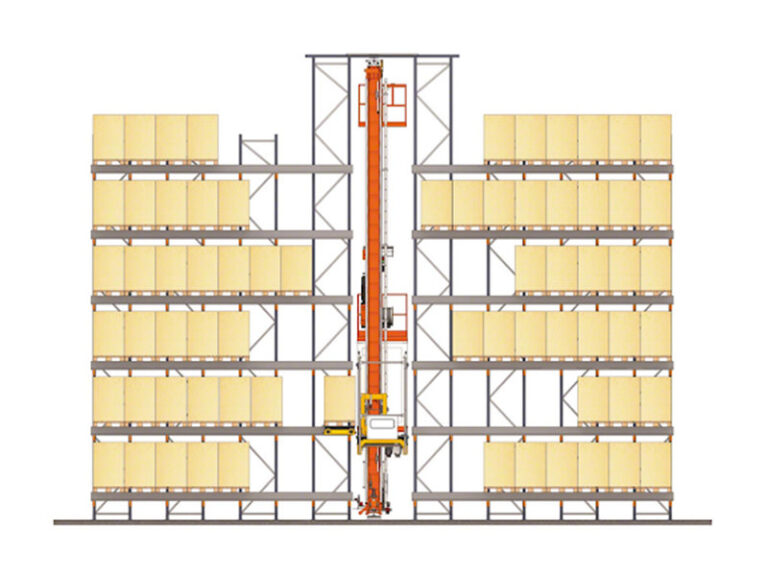

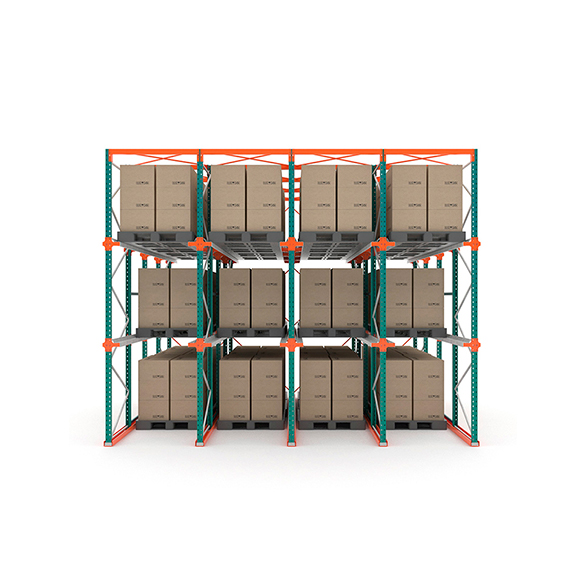

- $$ Call Now, Best Prices Guaranted $$ Push Back Pallet Racks Push Back rack systems use a dynamic cart-on-rail system in which deeper pallet loads automatically […]

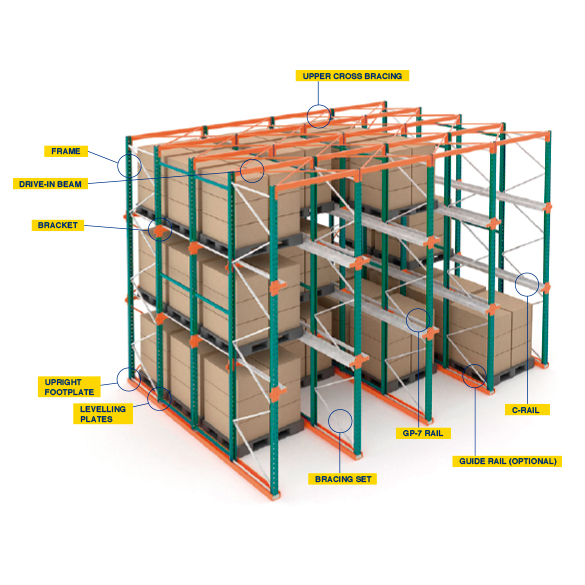

- $$ Best Prices of the Market $$ Drive Inn & Drive Thru Pallet Racks Drive-in racking and drive-thru systems are designed to store large stocks of […]

- $$ From 295 USD $$ Pallet Jacks Pallet jacks are manually operated used for moving one or more pallets at a time. Pallet jacks can be […]

- $$ Start Unit from 94 USD $$ Steel Shelving For decades, Steel Shelving has been the standard for inventory and parts storage within the warehousing industry. […]

- $$ Start Unit from 94 USD $$ Rivet Shelving One of the most popular storage solutions that we offer is our Boltless Rivet Shelving. With a […]

- $$ Start Unit from 605 USD $$ Cantilever Rack Cantilever racks use arms to hold products, which can be completely accessible from the front without any […]

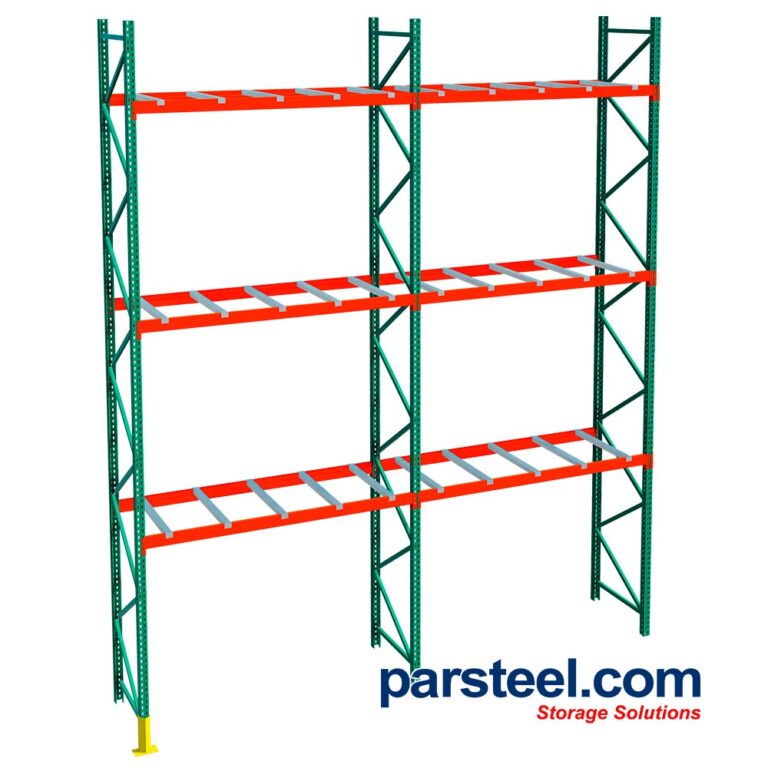

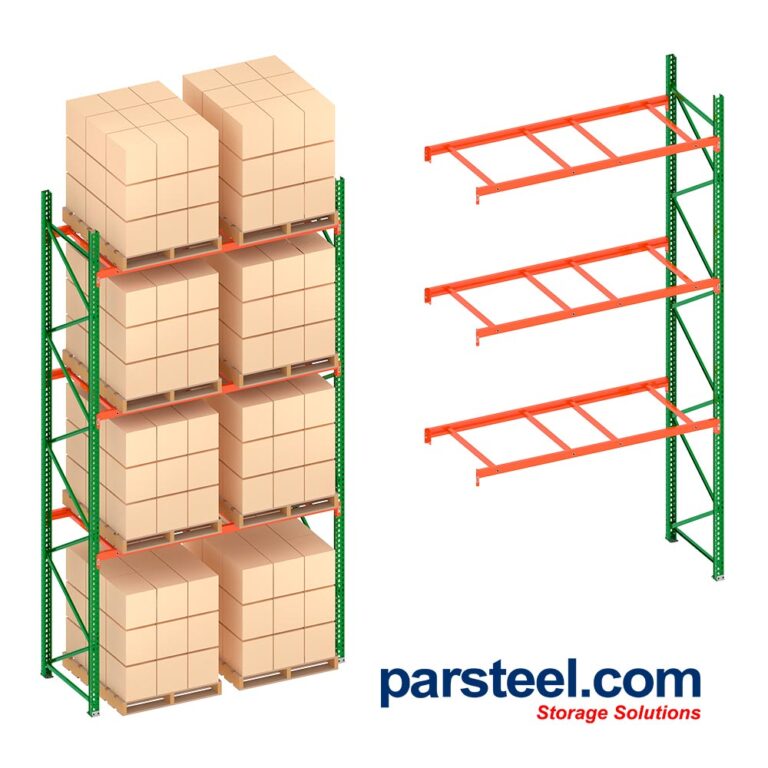

- $$ Start Unit from 219 USD $$ Selective Pallet Racks Distributor – Storage Solutions by Parsteel In warehousing, storage capacity and accessibility are the most important […]